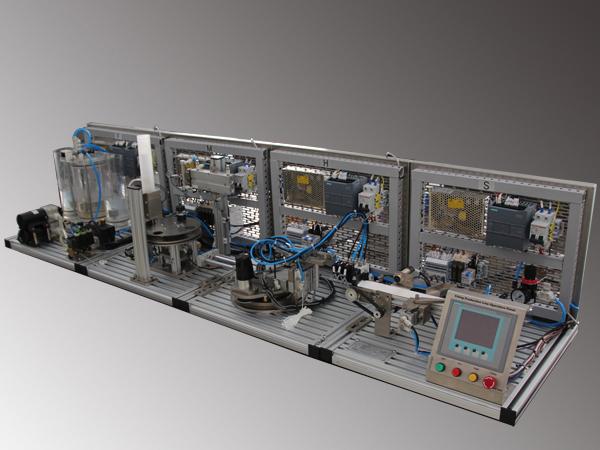

Model: DLPCS-400

Overview

The DLPCS-400 filling production line training system is designed according to process control and production flow, based on Siemens S7-1200 PLC control system. It has a modular structure, which makes it flexible and easy to expand. The system platform is made of aluminum alloy components and uses a variety of mechanical transmission modes to simulate filling production lines. It mimics the actual industrial production of electrical control parts, various sensors and modern production configuration control, and industrial bus full display in the system.

Technical parameters of the filling production line training system

Input power supply: single phase~220V±10% 50HZ

Working environment: temperature -10℃~+40℃;

Relative humidity 35%~65 % (25℃) Altitude <4000M

Capacity: ≤1kVA

Air pressure range: 0.4~0.6Mpa

Full size: 1350mm×460mm×390 mm

Each station: 450mm×460mm×390 mm

Experiment/Training projects

1. Pneumatic technology cognitive and application

Air pump cognitive

Air source processor cognitive

Vacuum Generator cognitive and application

Various cylinder cognitive

Solenoid valve cognitive and application

Magnetic switch cognitive and application

Air hose connection cognitive

Speed connector cognitive

Solenoid valve installation and debugging

Cylinder installation and debugging

Air source processor installation and debugging

Various cylinder maintenance

Various solenoid valve maintenance

2. Sensor technology cognitive and application

Photoelectric sensors cognitive and application

Fiber Optic sensors cognitive and application

Magnetic sensors cognitive and application

Inductive sensors cognitive and application

Vaious sensor connection

Various sensor fault diagnosis, maintenance and repair

Various sensor application

3. Mechanical transmission technology cognitive and application

Belt conveyor cognitive and application

Cylinder conveyor cognitive and application

4. Industrial automation technology principle and application

PLC principle and application

PLC programming method and application

PLC programming of filling station

PLC programming of assembly station

PLC programming of handling station

PLC programming of warehousing station

S7-1200PLC Ethernet communication

Stepper motor and stepper driver application

S7-1200 PLC motion control programming method

S7-1200 PLC PID control programming method

Touch screen configuration and application

5. Students can learn the following skills through system training:

Dynamic real-time monitoring

Learn programming language of PLC and PC controller

PLC programming language

LD (Ladder Diagram)

IL (Instruction List)

SFC (Sequential Function Charts)

FBD (Function Block Diagram)

ST (Structured Text)

Production flow application

Mechanical and pneumatic assembly application

How to choose electrical components

Pneumatic technology application

Various sensor applications

Electrical schematic design and standard requirement of components symbols

Rational arrangement of the disk

Various sensor installation and sensitivity adjustment,how to judge the sensor quality and related troubleshooting

Debugging process: cylinder debugging, motor pilot run, mechanical position adjusting, sensor debugging, collection of various types of signals, single station debugging and debugging after connection to networking

Trainer fault diagnose and repair