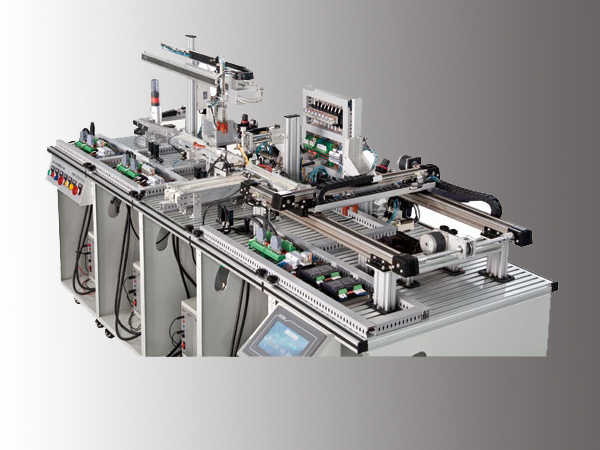

Model: DLDS-500A

Identical with the equipment used in the mechatronic project in the Olympic World Skills Competition

The DLDS-500A modular flexible manufacturing system trainer can be used for the trainings on mechanical assembly and commissioning, electrical installation and commissioning, as well as mechanical and electrical joint commissioning by module. Students can do independent programming exercises for each module and they can also do programming exercises for gradually extended combination module. We provide mechanical assembly diagram, electrical wiring schematic diagram, programming process step diagram, programming process, and sensor label table.

Our product can also be used for the development of modern product production process.

Application:

DLDS-500A modular flexible manufacturing system trainer can accomplish the grasping, stamping, assembly, dual-axis manipulator conveying, sorting and storing of three kinds of material blocks. This flexible manufacturing system can be used for training of students on the abilities of various techniques in professional fields. The techniques are machinery assembly, pneumatic component assembly, electrical apparatus element installation, circuit connection, electrical cylinder position adjusting, technical parameter setting of stepping motor, PLC programming technique, sensor technique and electronic technique.

Practical training system:

The system consists of grasping station, stamping station, assembling station, dual-axis manipulator station, stacking station, substrate, logical simulation box, PLC control box (optional types of programmable controller), operation panel, touch screen installation box, control box, I/O pinboard.

Main technical parameters:

1. Electric control cabinet main circuit power supply: single phase AC220V±10% 50Hz;

2. Electric control cabinet control circuit power supply: DC24V;

3. Temperature: -10℃~40℃; environment humidity: ≤90% (25℃);

4. Single station outline dimension: L×W×H=500mm×790mm×1200mm;

5. Bleed pressure: 0.4~0.6Mpa;

6. Complete machine capacity: ≤5KVA.

Practical training content:

Detection switch application

Multi-sensor application

Pneumatic component application

PLC application

Automatic storing management application

Two dimensional targeted grasping application

Pneumatic circuit connection and electrical wiring

Mechanical and pneumatic parts assembly and disassembly

System failure diagnosis and maintenance

Touch screen technique application

Data point to point sending and receiving

Cross station data transmission

Configuration software application

Related Names

Manufacturing System Integration | Manufacturing Automation Technology | Factory Experimental Machine | MPS