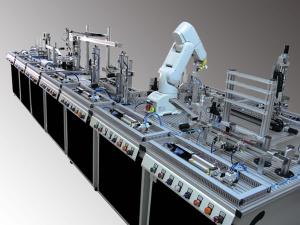

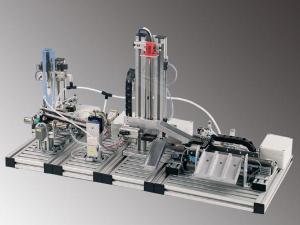

The DLMPS-800A modular flexible manufacturing system trainer includes eight work units or workstations, which are feeding station, handling station, processing station, handling and sorting station, conveyor station, handling and installation station, installation station, and classification station.

Technical Features

1. Dimensions: 790mm×3600mm×1280mm

2. Input power supply: single-phase three-wire 220V±10%, 50Hz/60Hz

3. Leakage protection: I△n≤30mA, t≤0.1s

4. Power supply output: 24V DC

5. Emergency stop button, power supply indicator

6. Power failure protection, inadvertent energization protection

7. Equipment capacity: ≤5KVA

8. Compressed air: 5~6bar

9. Height of table bottom to the ground: 750mm

10. Working environment

Temperature: -10℃~+40℃, relative humidity: 35%~65% (25℃), altitude: <4000m

Experimental item:

1. Pneumatic technology understanding and application

●Air pump understanding

●Source air processor understanding

●Filter understanding

●Vacuum generator understanding and application

●Various air cylinder understanding (pen type cylinder, dual rod cylinder, rotary cylinder etc.)

●Electromagnetic valve understanding and application

●Magnet switch understanding and application

●Pneumatic motor understanding

●Air pipe plugging and connection understanding

●Connector adjustment understanding

●Electromagnetic valve installation and debugging

●Air cylinder installation and debugging

●Pneumatic motor installation and debugging

●Source air processor installation and debugging

●Various cylinder maintenance

●Various electromagnetic valve maintenance

2. Sensor technology understanding and application

●Photoelectric sensor understanding and application

●Optical fiber sensor understanding and application

●Magnetic sensor understanding and application

●Current sensor understanding and application

●Eddy current proximity switch understanding and application

●Wiring methods of various sensors

●Failure diagnosis and maintenance of various sensors

●Wide application of various sensors on industrial field

3. Mechanical transmission technology understanding and application

●Belt transmission understanding and application

●Gear transmission understanding and application

●Chain transmission understanding and application

●Air cylinder transmission understanding and application

●Ball screw transmission understanding and application

4. Industrial automation technology principle and application

●PLC principle and application

●PLC programming methods and application

●PLC programming methods for feeding workstation

●PLC programming methods for operation workstation

●PLC programming methods for processing workstation

●PLC programming methods for installation and conveying workstation

●PLC programming methods for assembly units

●PLC programming methods for stereoscopic storing workstation

●PLC programming methods for conveying units

●PLC programming methods for conveying belt units

●PPI network programming methods

●Integrated programming methods for various workstation

5. FMS8000 modular production line understanding and application

●Connection between feeding and operating workstations and application

●Connection between operating and processing workstations and application

●Connection between feeding and processing workstations and application

●Connection between feeding and installation and conveying workstations and application

●Connection between feeding and assembling workstations and application

●Connection between feeding and sorting workstations and application

●Connection between feeding and conveying workstations and application

●Connection between feeding and belt conveying workstations and application

●Connection among various workstations and application

●Systematic and comprehensive abilities training

6. The learners can master the following skills according to systematic training:

●Dynamic and real time monitoring

●PLC and PC controller programming language learning

LD (Ladder Diagram)

IL (Instruction List)

SFC (Sequential Function Charts)

FBD (Function Block Diagram)

ST (Structured Text)

●Production process application

●Mechanical and pneumatic components assembly application

●Understanding the model selection application of electrical apparatus elements

●Pneumatic technology application

●Application of various sensors

●Electrical schematic diagram design and standard requirements of symbols of electrical apparatus components

●Understanding how to realize reasonable panel arrangement and wiring

●Installation and sensitiveness adjustment of various sensors. Understanding how to distinguish good sensors from bad ones and the handling methods of accidents.

●System debugging methods: air cylinder debugging, motor pilot running, machine position adjusting, sensor debugging, collection of various signals, debugging and further networking debugging of single workstation etc.

●Equipment failure diagnosis and maintenance

●Master CNC programming technology

Related Names

Manufacturing Production System | Factory Automation System | Product Manufacturing Process Trainer