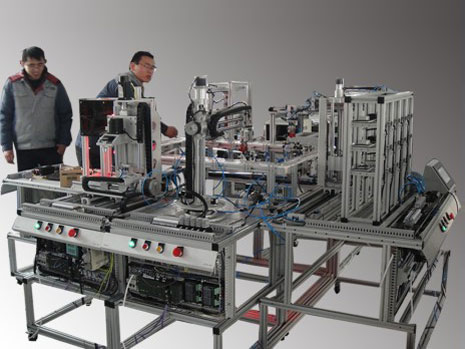

The DLFMS-8000 flexible manufacturing system trainer includes eight work units or work stations, which are transport station, processing station, detection system, sorting system, heat treatment system, automatic warehousing system, annular workpiece transmission system, and host computer management station.

This training equipment can complete the whole process from workpiece processing, detection, heating, cooling, sorting, to warehousing, truly reproducing the actual industrial manufacturing process.

Experimental Projects

1. Knowledge and Application of Pneumatic Technology

a. Knowledge of air pump

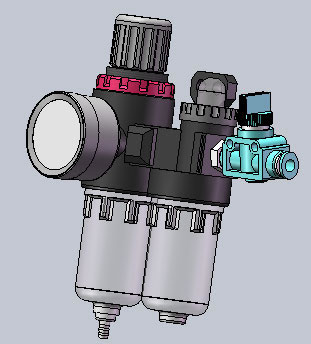

b. Knowledge of air source processor

c. Knowledge of filter

d. Knowledge and application of vacuum generator

e. Knowledge of various cylinders, like pen cylinder, double rod cylinder, rotary cylinder, etc.

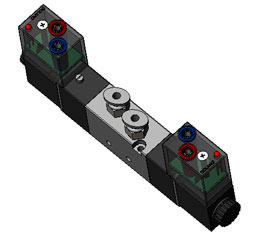

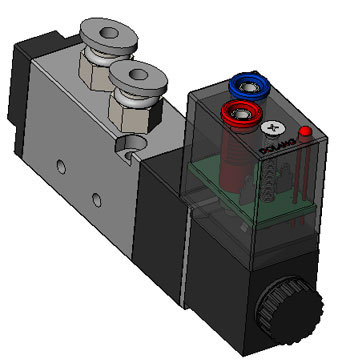

f. Knowledge and application of solenoid valve

g. Knowledge and application of magnetic switch

h. Knowledge of air motor

i. Air pipe connection

j. Knowledge of adjustment connector

k. Installation and commissioning of solenoid valve

l. Installation and commissioning of cylinder

m. Installation and commissioning of air motor

n. Installation and commissioning of gas source processor

o. Care and maintenance of various types of cylinders

p. Care and maintenance of various types of electromagnetic valves

2. Knowledge and Application of Sensing Technology

a. Knowledge and application of photoelectric sensor

b. Knowledge and application of fiber optic sensor

c. Knowledge and application of magnetic sensors

d. Knowledge and application of current sensor

e. Knowledge and application of electric vortex type proximity switch

f. Wiring methods of various sensors

g. Fault diagnosis as well as maintenance and repair of various types of sensors

h. Wide application of various sensors in the industrial field

3. Knowledge and Application of Mechanical Transmission Technology

a. Knowledge and application of belt conveyor

b. Knowledge and application of gear transmission

c. Knowledge and application of chain drive

d. Knowledge and application of cylinder transmission

e. Knowledge and application of ball screw drive

f. Principle and application of PLC

g. Programming method and application of PLC

h. DP network programming method

i. Programming methods of each station

4. Knowledge and Application of FMS8000 Modular Flexible Manufacturing System

a. Application of each station and contact between stations

b. Training on comprehensive abilities relating to the system

After training on this DLFMS-8000 flexible manufacturing system trainer, students are expected to master the following skills.

1. Dynamic real-time monitoring

2. Programming language of PLC and PC controller

PLC programming language

LD(Ladder Diagram)

IL (Instruction List)

SFC (Sequential Function Charts)

FBD (Function Block Diagram)

ST (Structured Text)

3. Application of production process

4. Application of mechanic al and pneumatic components assembly

5. Selection and application of electrical components

6. Application of pneumatic technology

7. Application of various sensors

8. Standard requirements of electrical schematics design and component symbols

9. Reasonable disk layout and wiring

10. Installation and sensitivity adjustment of various sensors; Learn how to evaluate a sensor and accident treatment measures

11. System debugging process: cylinder debugging, motor test run, commissioning of the mechanical position, sensor testing, acquisition of various signals, single station debugging, networking commissioning, etc.

12. Equipment fault diagnosis and maintenance

13. Master CNC programming techniques

Related Names

Control Automation System Experimental Device | Industrial Manufacturing Process Tester | Manufacturing Solution | CIM