Model: DLMPS-500B

Overview

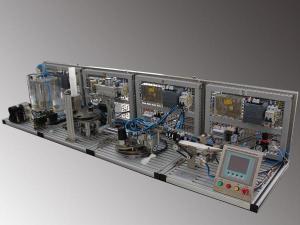

The modular flexible production system is a kind of flexible production system adopting PROFIBUS-DP bus structure. It can accomplish the processes such as workpiece distribution, inspection, processing, conveying and storing. It can realize true representation of practical industrial production process. Different workstations of this system can combine freely. It is easy to construct, disassemble and maintain different modules. The current working status of each workstation and data processing are all summarized on the master control platform. The platform can coordinate the relative actions of each workstation according to requirements. Finally, all the workstations can gently and coordinately accomplish the tasks given by the system.

The modular flexible production system mainly consists of five stations: distribution unit, testing unit, processing unit, robot handling unit, sorting and storage unit.

This manufacturing system increased the servo control method, and uses servo control in both the 3rd station and 5th station.

The modular production system software is controlled by MCGS industrial configuration monitoring software, which monitors the operation status and operation process of the equipment.

Technical parameters of the modular flexible production system

1. Input power: single phase~220V±10% 50Hz

2. Output power: 24V DC power supply

3. Leakage protection: I△n≤30mA, t≤0.1S

4. Installed capacity: ≤5kVA

5. Operating compressed air: 5~6bar

6. Working environment: temperature -10℃~+40℃; relative humidity 35%~65% (25℃); altitude <4000M

7. Breaker protection

8. Emergency scram button, power source indicator, power supply indicator

Specifications:

Total outline (L*W*H): 3000×790×1420mm

Single unit outline (L*W*H): ①600×790×1180mm; ②600×790×1410mm;③600×790×1260mm; ④600×790×1200mm; ⑤600×790×1420mm;

Training project

1. Distributing workstation

●Accomplishing PROFIBUS-DP network training;

●Accomplishing signal collection training from various slave stations;

●Practising installation of Step V5.4 Siemens 300 software;

●Practising application of network information processing technology in industry;

●Accomplishing website setting training;

●Accomplishing touch screen training;

●Practising touch screen software installation;

2. Testing workstation

●Accomplishing training of material block sorting by color via sensor;

●Accomplishing training of material block sorting by texture via sensor;

●Accomplishing training of material block sorting by height via sensor;

●Accomplishing qualified material block conveying training;

●Accomplishing training of unqualified material block treatment;

●Accomplishing sensor measuring training;

3. Processing workstation

●Accomplishing training of depth measurement of workpiece;

●Accomplishing training of simulating processing of workpiece;