Model: DLCIM-FL824

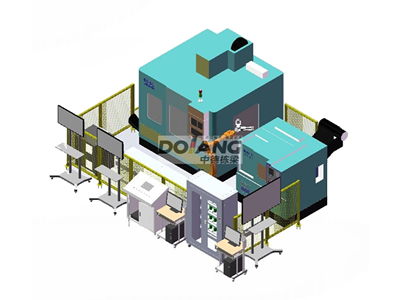

The flashlight automated manufacturing training system combines teaching, training, demonstration, real production together. This CIM system shows combining and application of various basic techniques in modern industrial control via simulating the industrial production, assembly and packing process of flashlight. The basic techniques include various advanced control technique and processing technique in industry field. When combining with course development, this training system can be used for most majors in institutes of science and technology.

Components:

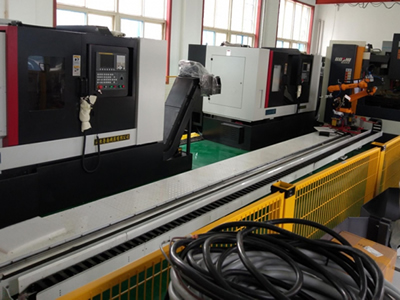

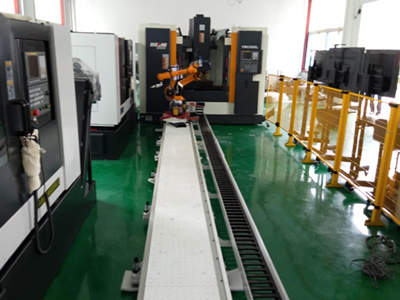

The flashlight automated manufacturing training system consists of Siemens RFID, S7-1200 PLC, frequency converter, Inovance servo system, touch screen, industrial robot, AGV, industrial visual inspection system, fiber laser marking machine, CNC lathe, CNC machining center etc.

Highlights of this flashlight automated manufacturing training system:

1. This flashlight automated manufacturing training system fills the gaps of the traditional training equipment with the real production. It adopts practical on site industrial components which are close to modern industrial production environment. So the learners can fully understand the on site industrial equipment sets and their combining modes and control methods.

2. It adopts modular structure design of which each work station is independent. The modules can work independently as well as unitedly. The studying of the learners can be sequentially from simple to complex.

3. The training system is the integrated modern and leading techniques such as PLC, AGV, machine vision, quick change technique of robots, testing and sensing technique, CNC machining, industrial robot, field bus line, industrial configuration software, modern logistic technique, laser marking etc.

Course content:

Robot practical operation: hardware connection of robots;

Robot demonstrator and computer debugging;

Robot I/O communication;

I/O signal monitoring and operation;

Robot program construction and programming;

Robot Ethernet communication function;

CNC machining: CNC system debugging, processing craft design, processing programming;

Visual guidance: communication sets between visual inspection and PLC, auxiliary visual software debugging;

RFID: communication sets between RFID and PLC, RFID wiring and signal collection;

Programming control: drawing of electrical schematic diagram and program flow chart, programmable controller programming and debugging, programming software application;

Communication control: Ethernet communication control, network system configuration and topological graph layout, PLC master station and slave station setting, communication between PLC, RFID and robots, variable communication between PLC and human computer interface;

Motor driving: servo motor positioning speed control, variable speed control of 3 phase gear motor;

Sensor detection: installation, wiring, signal collecting and debugging of photoelectric, inductive, capacitive, Hall and some other switch value sensors;

Machine installation and debugging: assembly tool, measuring tool and machinery accessories application, map reading, installation and debugging of mechanical executive system such as linear module, synchronous pulley, optical axis with supporting, work fixture etc.;

Gas circuit construction: gas circuit chart reading and drawing, gas circuit construction and installation and debugging of pneumatic executive components such as locking cylinder, 3-axis cylinder, wide gas claw etc.;

Low voltage distribution: wiring and debugging of buttons, indicator light, breaker, relay, tower light etc.;

Human computer interface: human computer configuration interface drawing and variable debugging, configuration software application;

Map reading and wiring: wiring tool, wiring accessories and wire size mark application, signal wire, power line connection.

Related courses:

1. Principles and applications of sensor

2. Automated production and manufacturing system

3. Electric control and PLC

4. Mechanical and electrical transmission and control

5. Computer aided design and manufacturing

6. Computer control system

7. Frequency converter technology and application

8. Industrial field bus

9. Process control

10. Industrial configuration software technology

11. Industrial robot

12. CNC machining

13. Mechanical design basis

14. hydraulic and pneumatic