Model: DLIM-201

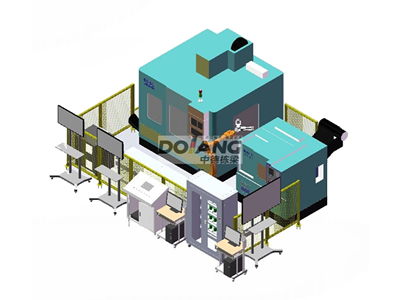

The DLIM-201 bottled water production training system integrates the functions of teaching, training, demonstration and real production together. This CIM system consists of filling and process control device, stacking training device, high-rise storage device. The automatic industrial production line consisting of these three sets of training devices can comprehensively show the techniques used during on site automatic industrial production process such as control technique, installation technique, pneumatic technique and sensing technique. The three parts of this production line can accomplish the production, filling, conveying, stacking and storing and some other processes of pure water, completely simulating the working process of the industrial pure water production process.

Training content:

When the DLIM-201 bottled water production training system is used for filtering and filling of pure water, it can be used for pressure control training, flow control training, liquid level control training, motor logic control training, programmable controller application training, sensor application training, automatic device training, pneumatic transmission and control training and some other training contents. This filling training system is a complex technique and highly automated system combining microelectronics, computer information technology, control technique, machine manufacturing and systems engineering together. The training contents include installation and debugging, failure diagnosis and trouble shooting, PLC programming and project design.

The DLIM-201 bottled water production training system can realize the following functional modules:

1. Purified water production module;

This module can realize filtering and purification of water and storage of purified water which can meet the standards.

2. Purified water filling module;

A. This module can realize filling a certain amount of purified water into bottles.

B. The bottles can be sequentially placed. And the movement of the bottles are controlled via program.

C. The filling finished bottles are capped by this module.

D. The filling finished and capped bottles will be conveyed to the next unit along the transmission line.

Technical index:

1. Input power: single phase and three line power supply (220V±10% 50Hz).

2. Working environment: temperature -10℃~+40℃, relative humidity <85% (25℃), altitude <4000m.

3. Installed capacity: <2KVA.

4. Working condition: no conductive particles, no chemical material which will be corrosive to metals and insulation layers. The application environment should have facilities which can protect the machine from rain, snow, wind and sand. There should be no vapour or severe mould pollution.

Features:

1. The DLIM-201 bottled water production training system adopts modular structure which means that each unit can work independently as well as unitedly.

2. Each module has its own programmable controller. All the PLC can be expanded with auxiliary modules.

3. Each module is attached with electrical connection terminals.

4. When pneumatic components are concentrated within one module, the connection with the control valve should adopt flexible pipes.

5. The installation platform is equipped with connecting ports of machines, electrical appliances, electrons and pneumatic units for control modules.

6. Silent air compressor: working power: AC 220V±10% 50Hz; power output: 0.75kW; power distributor and compressor; container capacity: 30L.

7. The system adopts visual control panel which can realize real time monitoring of running of each module via principal computer to ensure normal running of the system.