Model: DLIM-512MS

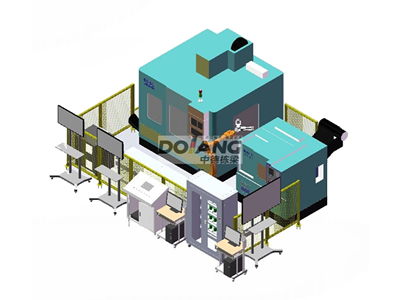

The DLIM-512MS intelligent manufacturing training system adopts classic mode of discrete manufacturing-intelligent manufacturing unit in mechanical cutting field. It combines the systems such as high level CNC lathe and industrial robot, intelligent sensing and control equipment, intelligent testing and assembling equipment, intelligent logistics and storing equipment and information based intelligent manufacturing system together.

Functions:

1. The DLIM-512MS intelligent manufacturing training system can be used for training of installation, debugging and maintenance of CNC lathe, industrial robot and some other mechanical parts, electric system, PLC control system and sensor.

2. With this system, the operators can control the intelligent manufacturing unit to conduct digital design of products, robot programming and control, CNC lathe programming and process optimization, accessory processing and online testing, product assembly and quality control etc.

3. The production carried out by intelligent manufacturing unit adopts informatization management. It uses manufacturing execution system (MES) to do order scheduling, process optimization, production task scheduling, product processing, equipment working condition real time monitoring. And the intelligent manufacturing line master control system can be used to do comprehensive treatment etc.

Technical parameters:

1) Input power:

CNC milling machine power: 3 phase four line power supply, 3PH, AC380±5%, 50Hz, 25KVA;

CNC turning lathe power: 3 phase four line power supply, 3PH, AC380±5%, 50Hz, 24KVA;

Industrial robot power: 3 phase four line power supply, 3PH, AC380±5%, 50/60Hz, 4KVA;

Control system power: single phase three line power supply, AC220V±10%, 50Hz, 3KVA.

2) Working environment:

Temperature: -10℃~+40℃,

Relative humidity: <85% (25℃),

Altitude without water condensing: <4000m.

3) Output power: DC stabilized power supply 24V/5A.

4) Equipment size: 6000*4800*2700mm (L*W*H).

5) Safety protection function: emergency stop button, safety lock, protective door.

The training items which can be accomplished by the DLIM-512MS intelligent manufacturing training system:

(1) PLC programming software installation and application;

(2) HMI touch screen programming software installation and application;

(3) CAM programming software installation and application;

(4) Industrial robot installation, debugging, programming and application;

(5) Industrial robot fixture installation, debugging, programming and application;

(6) CNC lathe installation, debugging, maintenance, programming and application;

(7) CNC machining center installation, debugging, maintenance, programming and application;

(8) CNC lathe online measuring, installation, debugging and application;

(9) Bus line communication technology application;

(10) Industrial automated network application;

(11) PLC technique application;

(12) Motor driving technique application;

(13) Motion control system application;

(14) Product assembling technique application;

(15) Industrial engineering application;

(16) Instrument and apparatus application;

(17) MES system application;

(18) Production safety etc.