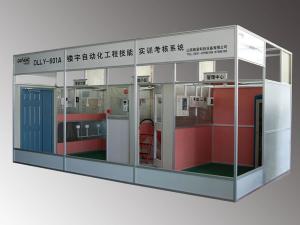

Model: DLSKB-C802C1

Overview of the CNC lathe comprehensive training equipment

The CNC system adopts Siemens a DLSKB-C802C1 base line X-axis and Z-axis that are driven by a servo motor. The spindle motor is driven by frequency converter.

This training device organically combines the machine's electrical parts with mechanical parts. It consists of a CNC system, frequency conversion spindle system, electrical control panels, power control section, servo drives and machine tool semi-physical simulation model.

Technical parameters of the CNC lathe comprehensive training equipment

Total dimension :1460×602×1700mm

Input power : three-phase, five-wire AC 380V±10% 50Hz/60Hz

Output power : AC 220V safety socket output

Lathe machine parameters :

Workbench moving stroke: X 200mm, Z 250mm

Maximum moving speed of the table : 3000mm/min

Maximum spindle speed : 1400r/min 25W

Lathe machine dimension : 670×450×180mm

Capacity : < 2KVA

Optional (System)

Siemens system

Fanuc system

HCNC

GSK system

Training content for the CNC lathe comprehensive training equipment

1. Hardware connection

a) How many parts composed of SINUMERIK 802 C base line system?

b) Which matters should be pay attention about I/O Link connection?

c) What role does the memory card slot?

d) Which kind of meet method of I/O signal?

2. Servo driver cognition

a) Know TECO appearance of servo driver

b) Installation method of servo driver

c) Wiring known

d) Encoder circuit known

e) Servo and motor connection circuit known

f) Installation method of braking resistance.

3. System electricity boot

a) What are the precautions system electricity?

b) How the order should be according to?

c) What conditions do the inverter needs when running?

4. The basic operation of the numerical control machine

a) SINUMERIK 802C base line numerical control system. What is its function?

b) What role soft key which on the left of the system with the left arrow and soft key that on the most right side with the right arrow?

c) What kinds of ways are there mode switch of machine tool operation panel, what are the role of each method is?

5. System debugging initial knowledge

6. System basic parameter setting

a) Which are there basic parameters of the system? What are the roles of each parameter is?

b) Which items are there initializations of servo parameters? How to set each item should be?

c) Which precautions have when use simulation spindle?

7. PMC programming debugging

a) Use ladder-diagram programming

b) Logic instructions programming

c) Function module chart programming

d) Which kinds of data form PMC there are?

e) Experience each soft key role and use in the PMC menu tree

f) Can through the PMC diagnosis the pictures and the ladder diagram picture monitoring the I/O signal state, and can modify PMC parameters

g) Can use memory card backup, restore system data.

8. The use of frequency converter

a) Understand the parameters meaning of the frequency converter, and will change the parameters

b) Master various control method of frequency converter.

9. Numerical control machine programming operation processing experiment

a) Numerically-controlled machine tool's programming operation below:

b) Specific use as shown in the practice instruction.

10. Numerical control system and servo unit parameters adjusting experiment

11. CNC machine disassembly training

a) The composition of the CNC machine tools and characterize understanding and use of CNC machine tool mechanical structure

b) The understanding and assembly of CNC machine function parts

c) CNC machine tool main drive and spindle parts structure

d) Structure of rolling ball screw pair.

12. NC machine tools precision testing and compensation technology training

a) Numerical control machine precision testing and commissioning

b) Machine precision testing principle

c) Machine precision testing analysis

d) Numerical control machine precision commissioning

e) Numerical control machine tool monitoring and compensation technology.

13. The numerical control system structure, the connection and commissioning training

a) The numerical control comprehensive test bed connection and debugging practice

b) Numerical control comprehensive test bed structure

c) The numerical control device basic link

d) The understanding and connecting of the numerical control system interface

e) Control and application of low voltage control circuit and PLC

f) Selection and application of the numerical control system sensor

g) Numerical control machine tool electric control system design principle

h) The parameter setting and experiment of numerical control device

i) Numerical control machine tool operation debugging training

j) The numerical control system PLC design and application

k) The test and operation training of servo system

l) Machine tool electric appliances disassembling training

m) Hidden dozens of troubleshooting.

14. Manual programming and simulation processing practice

a) Numerical control machine programming and simulation processing

b) The master of the numerical control program structure, format and command system

The understanding of system basic operation

Understanding numerical control machine tool basic processing technology.

c) Numerical control machine operation and programming processing practice

The master of numerical control machine program edits

The master of numerical control machine tool basic operation

Skills application of numerical control machine tool system function

Parts clamping and processing in the numerical control processing

Typical plane, 3d graphics spare parts programming and processing technology analysis

15. Understand common numerical control machine fault detection and maintenance training

a) The basic requirements and troubleshooting methods of CNC machine maintenance

b) Common fault diagnosis technology

c) Common fault inspection method

d) NC machine tools common faults and handle

e) Numerical control machine maintenance training

16. Understand the CNC machine tool installation, commissioning, acceptance training

a) Numerical Control Machine installation preparation

b) CNC machine tools are in place and installation

c) CNC machine tools melody level

17.Modify the procedure experiment

18. Servo drive circuit experiment

19. The knife

20. Fault setting and diagnosis, remove

21. CNC lathe machine processing programming basis

22. CNC lathe machine programming operation and processing examples

23. Electric tool installation debugging