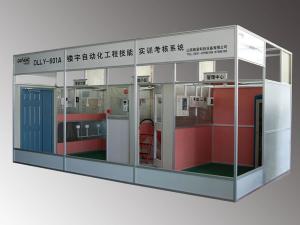

Model: DLSKP-C802S22

Overview of the CNC maintenance training assessment equipment

The CNC system adopts Siemens 802S series and a biaxial linkage. The main axis frequency conversion control adopts a three-phase hybrid stepping driving system. The system consists of an intelligent assessment system, CNC training bench and physical CNC lathe. It not only can act as maintenance training system of CNC lathes electrical wiring, but also as an actual processing device. The system has an electrical fault and maintenance assessment function. The assessment system uses DLWW-GX2.0 system assessment methods, it uses dynamic database link technology, and it can link student information.

Technical parameter of the CNC maintenance training assessment equipment

Working power : three-phase, five-wire AC 380V±10% 50Hz/60Hz

Capacity : < 5KVA

Safety protection : leakage protection (action current≤ 30mA) over current protection, overload fuse protection

Total dimensions :1580×500×1630mm

CNC lathe technical parameter:

The largest rotary diameter on lathe body : 350 mm

The largest rotary diameter on turret :150 mm

The fastest moving speed of working bench : 4000 mm/min

Maximum cutting feed speed : 2000mm/min

Optional (System)

Siemens CNC system

Fanuc CNC system

HCNC

Guangzhou CNC system

Training content

Training 1 Hardware connections for milling machine

Training 2 Hardware connection for lather machine

Training 3 Power on the system

Training 4 Basic operation for CNC machine

Training 5 Basic knowledge for system debugging

Training 6 Debugging for communication and serial

Training 7 How to use the CNC tool kits

Training 8 The operation for inverter

Training 9 Tool setting

Training 10 Basic knowledge of CNC processing programming

Training 11 Programming operation and machining

Training 12 Trouble assessment