Model: DLXKN-X808D

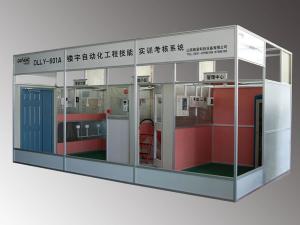

Overview of the CNC milling skill training assessment system

The CNC system adopts Siemens a DLXKN-X808D base line X-axis and Z-axis that are driven by a servo motor. The spindle motor is driven by frequency converter.

The training assessment device can complete a number of teaching and training operations such as CNC system installation, parameter setting, fault diagnosis and maintenance, CNC programming and machining operation.

Technical parameter of the CNC milling skill training assessment system

Working power supply : three-phase, five-wire AC 380V±10% 50Hz/60Hz

Control power supply : DC 24V

Capacity : < 8KVA

Total dimension : 1455×640×1700mm

Safety protection : leakage protection (action current≤ 30mA) over current protection, overload fuse protection

Milling machine semi-physical parameter :

Workbench moving stroke: X 120mm,Y 150mm,Z 120mm

Maximum moving speed of the table : 3000mm/min

Maximum spindle speed :1400r/min 25W

Milling machine semi-physical dimension : 939×740×1520mm

Optional (System)

Siemens system

Fanuc system

HCNC

GSK system