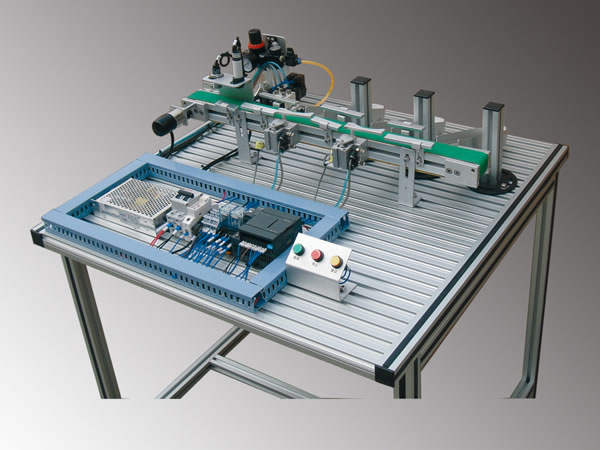

DLPLC-DCD1 Conveyor Belt Drive Training Equipment

The DLPLC-DCD1 conveyor belt drive training set combines PLC, proximity sensor, DC gear motor, limit switch, solenoid valve, and pneumatic mechanism. Through sensor signal collection and PLC programming, it controls the DC gear motor to realize automatic feeding control.

1. The belt transmission training equipment consists of the driving device, detection device, and carrying device. The DC gear motor drives the car to move through the synchronous belt. The sensor collects signals and the precise positioning control of the car is completed by the PLC. The cylinder and vacuum generator are controlled to act through the solenoid valve, thus completing the loading, unloading, and moving of materials and parts.

2. Our conveyor belt drive training set helps to complete the trainings on basic skills, professional skills, and post skills through the whole process from project content drafting, project analysis, project implementation, project summary, to ability assessment.

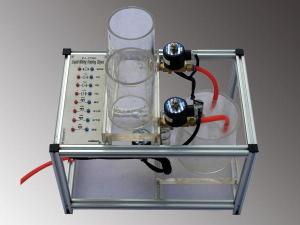

Experimental Training Content

1. Application of multiple sensors

2. Assembly and disassembly of the mechanical part and the electrical part

3. System fault diagnosis and maintenance

4. Pneumatic circuit connection and electrical connection

5. Design and application of sorting transmission

6. Find and correct the errors of the electrical circuit

7. PLC basic instruction exercises

8. Connect electrical lines

9. Write instruction program

Related Names

PLC System Trainer | Feed Control Training Equipment | Online Training Technology