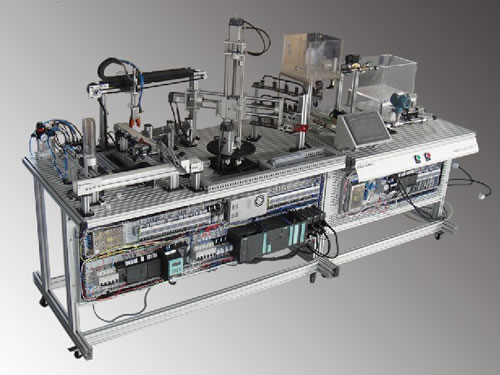

DLFA-321 Programmable Control System Designer Training and Testing Equipment

Model: DLFA-321

The DLFA-321 PLC control system designer training and testing device can be used for two parts of training, i.e., motion control training and process control training. It uses Siemens PLC as the controller. The master station adopts Siemens S7-300 series hosts and the slave station adopts Siemens S7-200 series hosts. The master station communicates with the slave station through MPI or RS485.

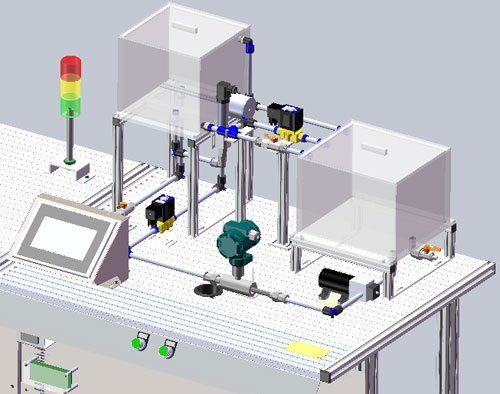

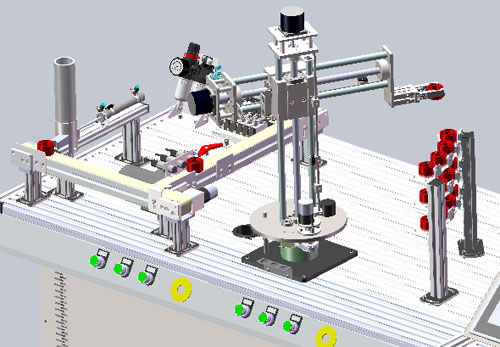

The motion control module includes automatic feeding unit, conveying unit, manipulator handling unit, and storage unit. The process control module contains analog variable measurement unit and PID adjustment unit.

Product Features

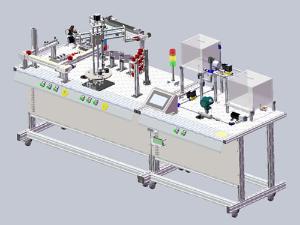

1. Our PLC control system designer training and testing device adopts an open style structure. Students can make up different execution system on the aluminum base plate according to different control plan.

2. Training projects that can be conducted on this training and testing device include PLC application training, frequency converter application training, touch screen application training, DC motor control training, stepper motor control training, and three-phase AC motor control training.

3. Process training includes analog variable, such as temperature, pressure, and flow, collection and output control.

4. The three-dimensional simulation software can realize online monitoring function and offline simulation function.

Equipment Composition

1. Training Platform

Made of aluminum alloy; all components are mounted on the aluminum base plate or mesh plate to facilitate dismounting.

2. Motion Control System

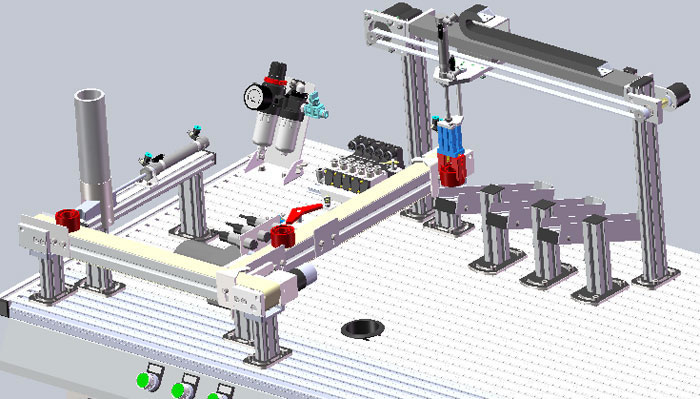

a. Automatic feeding unit

A well type feeding mechanism; the optical fiber sensor detects the storage bin; if there is workpiece in the storage bin, the pneumatic pusher will push the workpiece to the belt conveyor.

b. Belt conveying unit

After the workpiece is detected, the conveyor A will be started through the frequency converter. Meanwhile, the conveyor B will be started by the DC motor. The sensors installed around the conveyor B will detect the color and material of the workpiece and pass the workpiece information to the next work unit.

c. Manipulator handling unit (gantry manipulator)

The gantry manipulator will grab and release the workpiece according to the information from the previous work unit.

3. Process Control System

The process control system of this training and testing device integrates PLC, temperature sensor, pressure transmitter, flow sensor, water pump, and solenoid valve. Through sensor collecting signals and PLC programming, the system can realize complex switch control and sequential logic control for solenoid valve and water pump, so as to achieve flow, pressure, and temperature open-loop and closed-loop automatic control functions.

4. Automatic Warehousing Unit

The automatic warehousing unit consists of a rotary manipulator and a three-dimensional storage shelf. It can store workpiece by category according to the detection result from the motion control system.

Related Names

Programmable System Trainer | Industrial Control System Trainer | Motion Control Experimental Unit